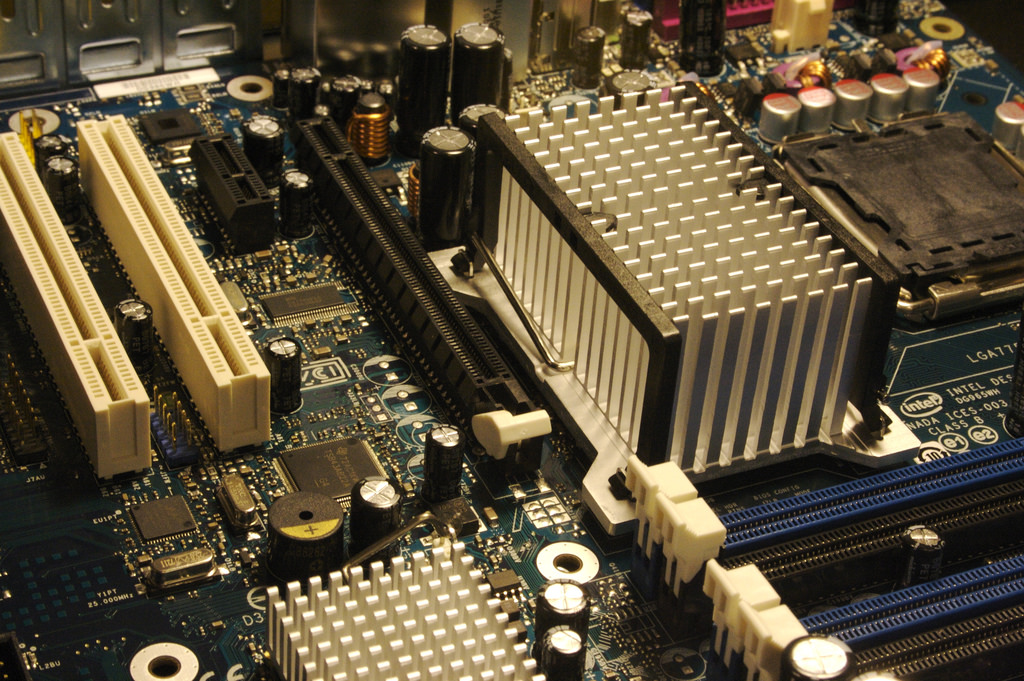

Printed Circuit Board or PCB was fabricated by the Austrian scientist Paul Eisle in the year 1936. Firstly, it was utilized by the American military in the Second World War in their bomb detonator units, but today it is used in various applications. Today, PCBs are found in almost all electronic components for instance Television, Radio, Smart phones, Tablets, Computers, Automobiles, and much more. So all in all, the presence of printed circuit boards can be seen everywhere around us. Not to mention, printed circuit boards are the indispensible part of every electronic item we see these days.

Brief introduction about PCB manufacturing

It was first manufactured with the help of 2 kinds of software which are named as CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing). As the names suggest, CAM software is utilized to design the electronic representation of the circuit to be created and the CAM software is utilized by makers to do circuit board manufacture.

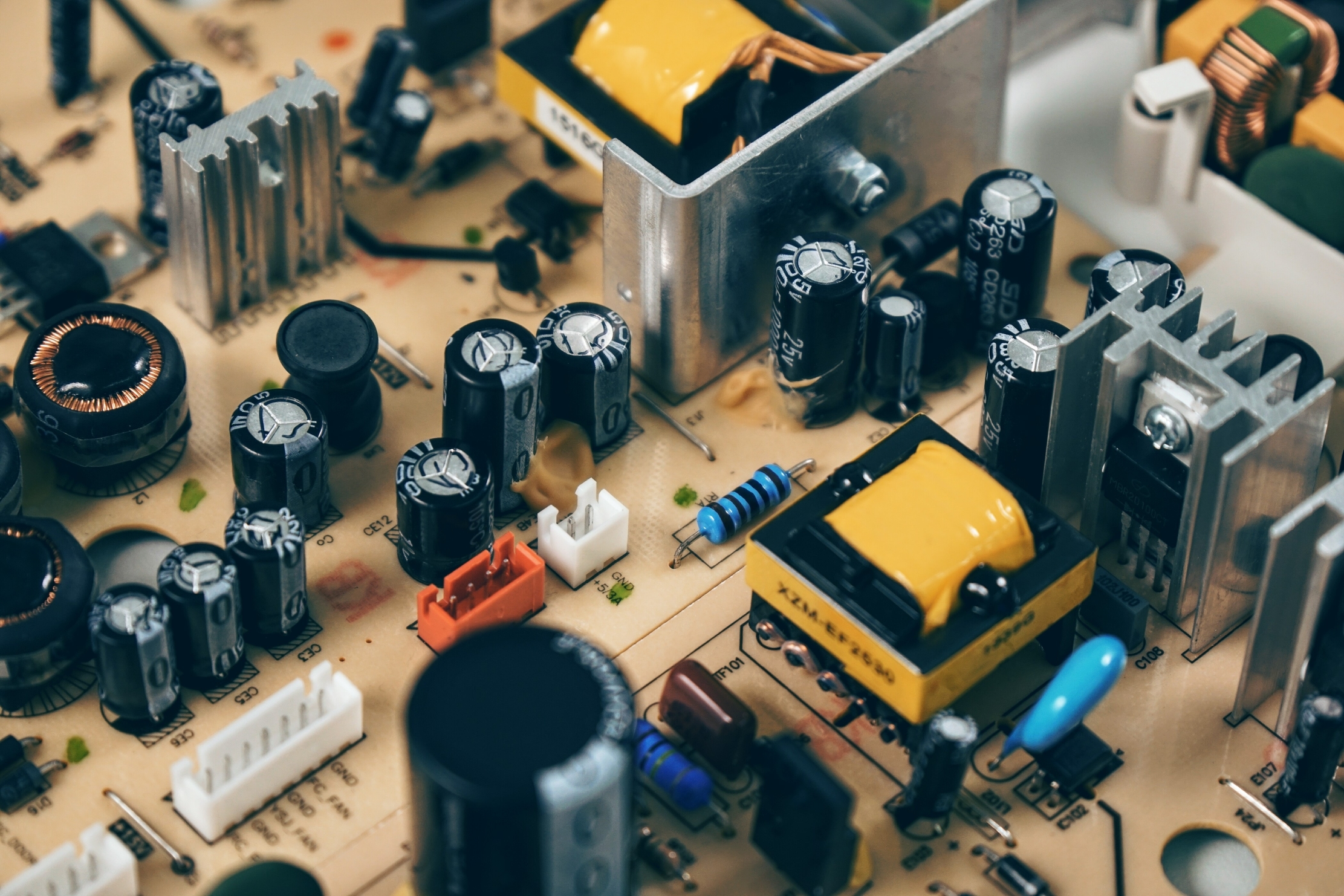

As soon as the prototype of the PCB is fabricated, the initial step in the manufacturing procedure is to choose the material of the PCB. There are a lot of different kinds of PCB materials accessible, nonetheless the eminent ones, rooted in the application and a client’s needs comprise: Bakelite, FR1 and 4, CEM5 and 1, Ceramic and more. The fabrication need gestures the dimensions of the PCB.

Once the material is picked, the primary procedure is to do a laminating of copper to the whole board.

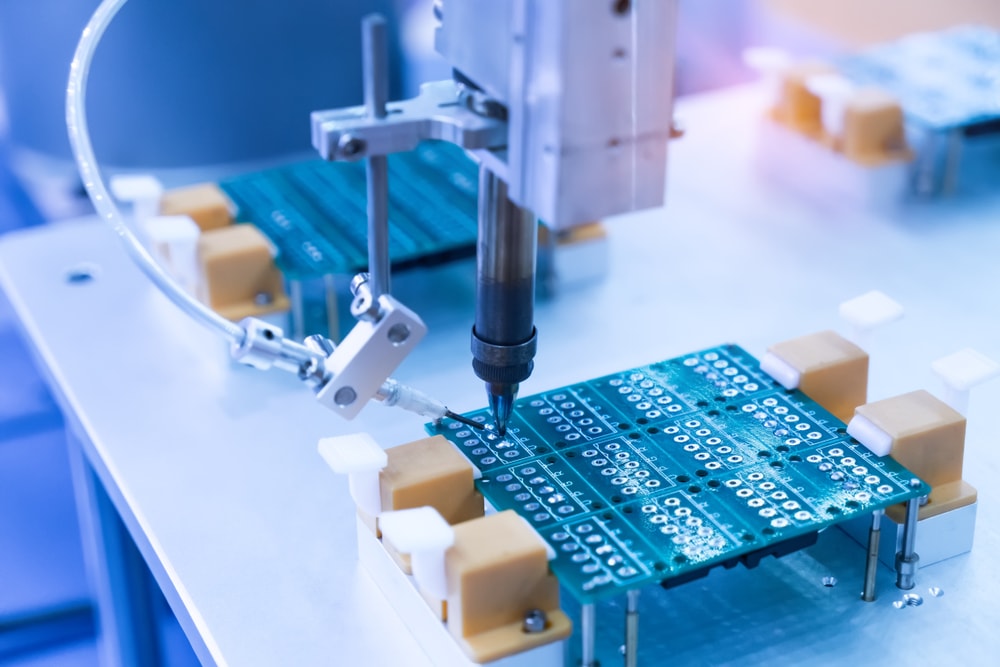

After that the photosensitive procedure is utilized in which the circuit layout would be printed on the board. After that a photo etching procedure will be utilized in order that the entire copper which is not the portion of the circuit will be eradicated from the board. The remaining copper produces the traces of the Printed Circuit Board. To put together the traces, two procedures are utilized. A CNC machine is used with the milling procedure to eradicate the needless copper from the board.

At this end in the Printed Circuit Board manufacturing procedure, the PCB board includes the traces of copper without any circuit elements. To mount the elements, holes are drilled at the tips where the electronics elements are put on the board. Typically, laser or Tungsten Carbide drill bit is utilized to make the holes. After the holes have been drilled, hollow rivets are popped into them or they’re laminated by the process of electroplating, that develops the electrical connection among the board layers. After that masking material (which is made up of lead solder, hard gold etc.) is used to laminate the whole PCB (but not on Pads & holes). The last step calls for screen print the board.

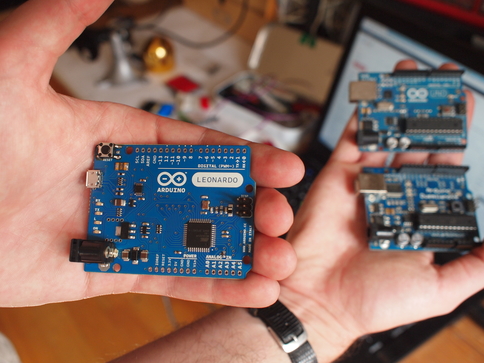

When you are looking for electronic assemblies manufacturing or in need of taking the services of a PCB manufacturer, you are required to pay attention to a few things which we are going to discuss in this article as you deserve to get one of the best PCB manufacturers for your company. These 5 points are given below. Make sure you follow these points in order to get the one your company deserves.

1) Where it is situated?

Make sure it is located within a drivable distance from your company as it will provide your business with more flexibility and dexterity to become familiar with altering conditions particularly when a deadline is about to coming up. A PCB manufacturing firm which is in your area provides a lot of other benefits also such as when site surveys are required to be performed, and more.

2) Do they have quality manufacturing equipment?

Make certain that your PCB contract manufacturer has quality manufacturing equipments to fulfill the general or unique needs of your company. Ensure that they utilize modern equipments to assure the quality of the end product. Also, find out the maintenance of pick and place machines, soldering machines, etc. if you can. Look at the maintenance logs of the company in order not to compromise with the quality. These things build trust.

3) Are the technicians experienced and certified?

To make certain that the PCB contract manufacturer can be able to accomplish your fabrication run on time calls for not only quality equipments but also a team of experienced technicians. So ask the company to provide the relevant credentials of its staff. Make certain they have required knowledge and certificates so that they can accomplish their assigned work successfully.

4) Does the company follow any quality systems?

Make sure that the manufacturing company should follow a quality system for instance ISO 9001:2008, or the similar. This thing will assure that the company can deliver high quality services. Beware of the companies which are not certified.

5) What about the pricing?

Keeping in view of the fact that labor charges are not the same in every place, you should attain an itemized go down of the net pricing of manufacturing. Look on cautiously what has been given in the manufacturing pricing. Then you are supposed to carry out a price comparison assessment to make sure if their prices are proportionate to the market average and of course with their competitors. Just make certain you have spent a decent amount of time in comparing the prices of different companies offering the same services in order to get the best.

You can Google the companies by writing the relevant keyword in the search bar and choose the finest for your company.